By Michael Lojkutz, Director of Marketing

In this article you will find:

- How our warehouse design supports efficient, high-volume manufacturing and fulfillment

- The technologies and protocols we use to ensure product safety and quality

- Why our facility offers the flexibility and reliability today’s supply chains demand

Tucked behind the hum of aseptic fillers and the steady rhythm of 18-wheelers at the dock bays, there’s a quiet precision to a well-run warehouse. Ours wasn’t built just for storage. It was designed for flow, flexibility, and the kind of reliability partners can count on.

Inside, electric forklifts transport fully loaded pallets with ease, moving in sync with automated pallet runners that maximize deep-lane storage and maintain FIFO (first in, first out). This setup reduces forklift operator touchpoints, minimizes damage, and protects both product and people. Wide aisles ensure safe, smooth movement, keeping the environment clean, quiet, and efficient.

With 17 dock doors and expansive staging areas, our facility is built to move. Whether it’s the steady rhythm of daily orders or the surge of seasonal demand, stopping is simply not an option. From full-pallet orders to pallet-layer picking, we provide the flexibility today’s supply chains demand.

We’re proud to be SQF certified, with rigorous protocols in place to protect your products and your brand. Cleanliness, traceability, temperature control, and documentation are built into our everyday process. Our team is trained. Our systems are tested. And our standards are high.

What does it mean to be SQF Certified?

To become SQF (Safe Quality Food) certified, a facility must meet rigorous global standards for food safety and quality. The process involves hundreds of steps and requires companies to be audit-ready at all times. The first audit is announced, but every third audit is unannounced, occurring within a three-month window, with the facility allowed to provide blackout dates.

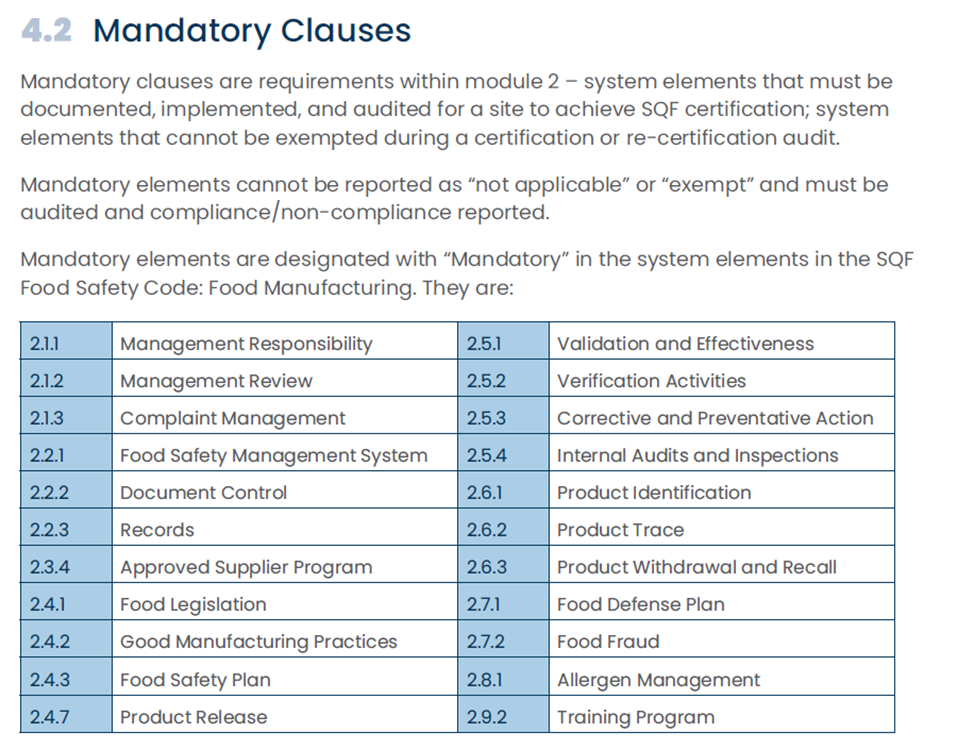

A key part of certification is compliance with 28 mandatory stipulations, including a Food Safety and Quality Management Plan. Failure to meet any of these can result in a critical finding. Extensive documentation is required—every task must be written down, showing what was done, by whom, how it aligns with policy, and that it was properly verified.

This is more than square footage. It’s a space designed for performance. In order perform at its peak, we put in place with the people, processes, and mindset to match. Whether you need long-term storage, cross-docking support, or full-service fulfillment, you’ll find it here. We guarantee it will be done right, done on time, and done with care.