By Tara Jewell, Marketing Manager

This is the second in a multi-part series on how we help customers optimize all aspects of their beverage program. Miss the first post? Catch up here. Market fluctuations, ever-changing regulations and soaring costs are beyond our control. From R&D to Sourcing and Logistics, our team can help you navigate the factors that are within your control.

In this article you will find:

- A clear explanation of how aseptic manufacturing works—and why it’s ideal for high-acid beverages

- Real-world examples of how aseptic packaging drives efficiency, sustainability, and ease of use in foodservice

- A breakdown of operational benefits you might be overlooking, from storage to shipping to waste reduction

If you’re still packaging your high acid beverage in PET bottles, it’s time to consider a switch. Aseptic isn’t a trend– it’s a proven solution trusted by brands around the globe. Because it yields a superior product in terms of flavor, sustainability, efficiency and safety, aseptic manufacturing is the ulimate optimzation move. Let’s take a closer look at how.

Aseptic Manufacturing: A Quick Definition

Aseptic manufacturing is a process in which both the beverage and its packaging are sterilized separately, then combined in a sterile environment. The result? A shelf-stable product that requires no preservatives or refrigeration, while maintaining high safety and quality standards. It’s especially effective for high acid beverages like juice, lemonade, tea, and fruit-based refreshers.

If you need more detailed information on aseptic processing, we’ve got a blog for that too.

You already know aseptic extends shelf life and protects product quality. That, however, is not the whole optimization story we can tell. Let’s explore some less obvious, but equally valuable, ways aseptic can drive operational efficiency across the board.

Packing Efficiency

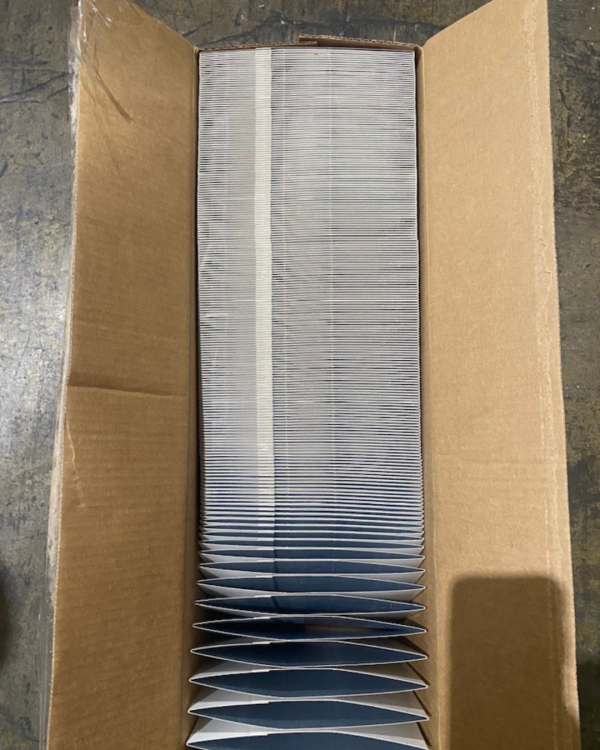

Optimization is evident throughout the lifecycle of an aseptic product– even when the cartons are shipped to our facilities. When aseptic cartons arrive at our manufacturing facilities, they are flat, enabling them to be stacked by the hundreds in the shipping box. Compare that to PET bottles, where dome-top bottles don’t fill every inch of a square-shaped box. Essentially, operators are paying to ship air. When manufacturing at the high volumes that we do, every inch of wasted space adds up to more shipments and more trucks on the road, and more gas being used….you get the idea. It’s a sustainability (and a cost!) thing.

Speaking of sustainability, this isn’t limited to aseptic (and it’s not in all aseptic) but in terms of Leahy products, we concentrate our products for most of our customers. When it arrives at the operator’s facility, they reconsitutue the product; the operator didn’t pay to ship water. So, for example, in a 32 oz. carton of 3:1 concentrate, the operator will add 96 oz. of water, yielding a gallon of product. Again, fewer shipments = more sustainable. Depending on the product or desire of the customer, we can also formulate to fid that ideal concentration.

Shelf Stable Before Opening

If you’ve never worked in foodservice, you might not know that back-of-house storage space is at a premium. This is true in any commercial kitchen, but the problem is becoming even more pronounced with the proliferation of the cube-style, drive-thru footprint, now the favorite of QSR coffee chains like Biggby and Dutch Bros. With this small footprint, operators must make smart use of every square inch of space. The most precious space, of course, is cold storage. Cold-storage space is more costly per square foot, and, well, it can’t be used for anything but to store items that must be kept cold. Therefore, a product that doesn’t require refrigeration is always going to be more optimal. Before opening, an aseptic product can be safely stored at ambient temperature. Additionally, the geometric shape of the combi carton fits neatly on dry storage shelf spaces. With our concentrated products, we’re providing a lot of product in a small, easy-to-store package.

Cold Storage, Without the Chaos

Now of course, most (*but not all) of our products will require refrigeration after opening and when reconsitituted. But even when in cold storage, an aseptic combi carton is just enough more optimal so that, at scale, things get just a little easier for day-to-day operations.

Here’s why. We’ve all stored plastic water bottles in a refrigerator. Thanks to the wire shelves that most refrigerators are equipped with, the bottles are precariously balanced inside, one minor disturbance away from a water bottle avalanche. If you’ve ever stocked an under-counter fridge with glass beer bottles, for example, you’ll be familiar with the avalanche to which I’m referring.

Now imagine this chaotic scenario in a busy QSR– at thousands of locations around the country. Surely such an operation can still run with a PET bottle equipped with a petaloid base, the common five-lobed design found at the bottom of many PET bottles. But at scale, bottle avalances all over the country can be rather disruptive, causing headaches for busy teams. Headaches, by the way, that make coming to work just that much less enjoyable.

The aseptic carton sits perfectly flat on the wire shelves. The perfect geometric shape means they stand neatly in line, a formation that creates a clean and satisfyingly neat situation in your cold storage. Anyone would prefer to work at an operation that runs smoothly, and aseptic cartons make one small contribution to an operation running smoothly.

This tidy, optimal storage setup also improves service time. Instead of digging around a cluttered fridge to find the right bottle, team members can quickly identify and grab the product they need. When every second counts during peak hours, that organization adds up.

Better Barrier = Better Product

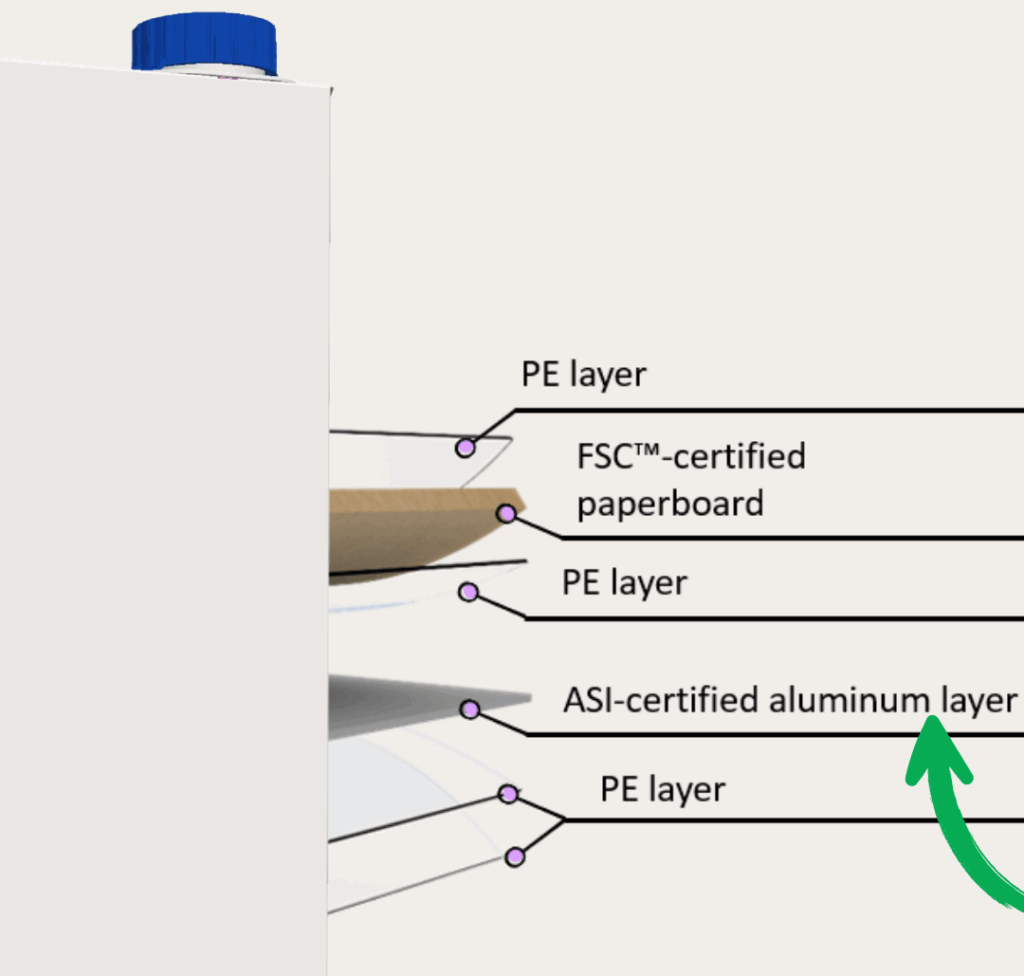

Ever seen a plastic water bottle caved in at the center? That’s oxygen penetrating the plastic. While plastic feels solid, it’s not a true barrier; small molecules like oxygen and water can pass through. And oxygen is the enemy of shelf life: it reacts with flavors (causing off-notes) and with colors (leading to fading or discoloration).

Aseptic cartons solve for that. They contain an ASI-certified aluminum layer, which creates a nearly impenetrable barrier to oxygen, light and moisture. That means brighter flavor, better color, and longer-lasting product quality.

Compact Trash

If you think taking out the trash is a dreaded chore on the domestic front, try doing it at a restaurant during peak hours. Restaurants of all sizes create massive amounts of trash, and it has to be dealt with quickly and efficiently. When business is buzzing, bins in the store fill up quickly. Then, the clumsy bags must be lugged to a smelly dumpster… it’s messy, annoying and no one wants any part of it.

In an operation that is using PET bottles, bins fill up especially fast– requiring more trash runs per shift. Meanwhile, aseptic cartons collapse easily and are lightweight. They take up less space in the recycling bin, meaning fewer trash runs throughout the day. On top of that, using aseptic cartons requires fewer recycling pickups. That’s because in an average 8-yard dumpster (which is the size of the dumpster in the back of many resturants), you can fit over seven times more flattened aseptic cartons than 1-liter PET bottles.

That translates to fewer trash runs, fewer pickups, and a cleaner, more efficient operation. It’s a small change with major downstream impact.

Aseptic manufacturing does more than just extend shelf life. It streamlines packing and shipping, simplifies storage, reduces waste, and supports smoother day-to-day operations.

It’s not just a manufacturing format—it’s a strategic decision that touches every part of your beverage program.

*Curious about the potential for a shelf-stable, clean label formula—one that doesn’t require refrigeration even after opening? Our Innovation and R&D teams are always exploring new possibilities and would be happy to discuss what might work for your operation.